BLENDING & DISSOLVING SYSTEMS

Inline Technology for On-Demand, High-Purity DEF Production.

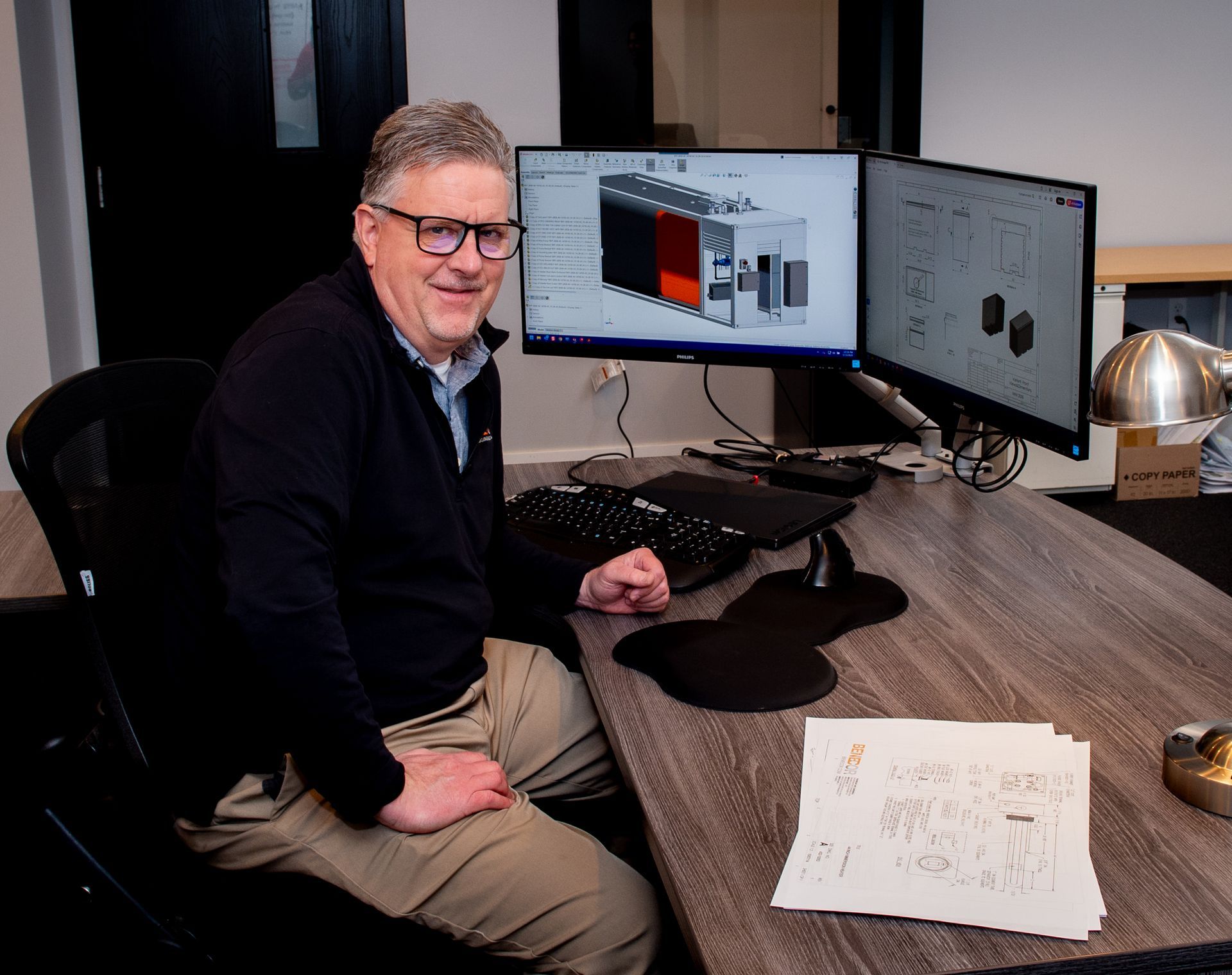

Benecor offers the most advanced “Plug & Play” Inline Blending & Dissolving Systems on the market—engineered to help you produce high-quality diesel exhaust fluid with precision, efficiency, and minimal operator involvement. Compact enough to fit in a single 40' container and customizable to your volume needs, these systems are built for high-capacity production with ISO 22241-compliant performance.

EngineerED FOR Customization

Benecor’s systems are designed to scale with your operation, offering blending capacities of 1.050, 2.375, or 4.750 gallons per hour. Using Siemens PLC control and inline refractometers, the system provides automated DEF production with constant monitoring and remote supervision capabilities.

System Features & Components

Heat Plate Exchanger

Uses hot water or steam to achieve optimal inline blending temperature (86°F / 30°C), ensuring DEF purity and consistency.

DEF Debagging Unit

Available in 2m³, 4m³, and 7m³ hopper sizes with built-in top grid sieve, minimum load sensors, and optional urea crusher integration for lump breaking.

Screw Conveyors

Fully integrated screw conveyors streamline movement through the blending and dissolving process for continuous, efficient production.

Double Reverse Osmosis Water Treatment System (DRO WTS)

Produces high-purity demineralized water at rates of 264.1, 528.3, or 1,320.8 gallons per hour, meeting ISO 22241 water standards.

Smart Monitoring & Control

- Inline refractometer for constant concentration monitoring

- 24/7 autonomous operation

- Remote access and system control via Siemens PLC

Compact, Scalable & Compliant

- Fits within a single 40' container (excluding DEF and water storage)

- Made with ISO 22241-compliant materials

- Designed for 24/7 operation with minimal operator involvement

- Ideal for industrial-scale DEF production and distribution hubs