Article

When Temperature Matters, Details Matter Even More

How Benecor engineered a 20,000-gallon insulated tank to keep a critical chemical right where it needs to be

Engineering a Reliable 20,000-Gallon Heated Storage System for GPAM

A paper mill in North Carolina required a 20,000-gallon insulated and heated chemical storage system for glyoxalated polyacrylamide (GPAM), a temperature-sensitive, water-soluble polymer critical to paper strength and production consistency. With a specific gravity of 0.95–1.05, GPAM must be maintained within a controlled temperature range to preserve chemical integrity, pumpability, and performance throughout the production process.

Even in moderate climates, winter temperature fluctuations create significant challenges for storing temperature-sensitive chemicals. Exposure to low ambient temperatures can increase viscosity, cause phase separation, and alter chemical properties, leading to handling difficulties and inconsistent performance. In polyethylene tanks, improper thermal management can also introduce structural stress, increasing the risk of cracking, operational disruption, and safety concerns. Because GPAM directly impacts finished product quality, maintaining reliable temperature control is essential to uninterrupted mill operations.

Before engaging Benecor, an alternative solution under consideration was a refurbished tank that had previously been used for another application. While this approach may have reduced upfront cost, converting the tank for GPAM storage would have introduced additional complexity, limitations, and long-term maintenance concerns. Retrofitting heating, insulation, and controls into an existing system can create inefficiencies and operational risk, particularly for a temperature-sensitive chemical critical to product quality. The customer ultimately sought a solution that would integrate seamlessly into their process rather than require ongoing workarounds.

Benecor brings extensive experience designing and manufacturing engineered chemical storage systems for temperature-sensitive industrial applications, including polymers and caustic chemicals used throughout the paper industry. Rather than supplying a standard tank, Benecor developed a fully integrated storage solution engineered specifically for GPAM and the environmental conditions at the installation site.

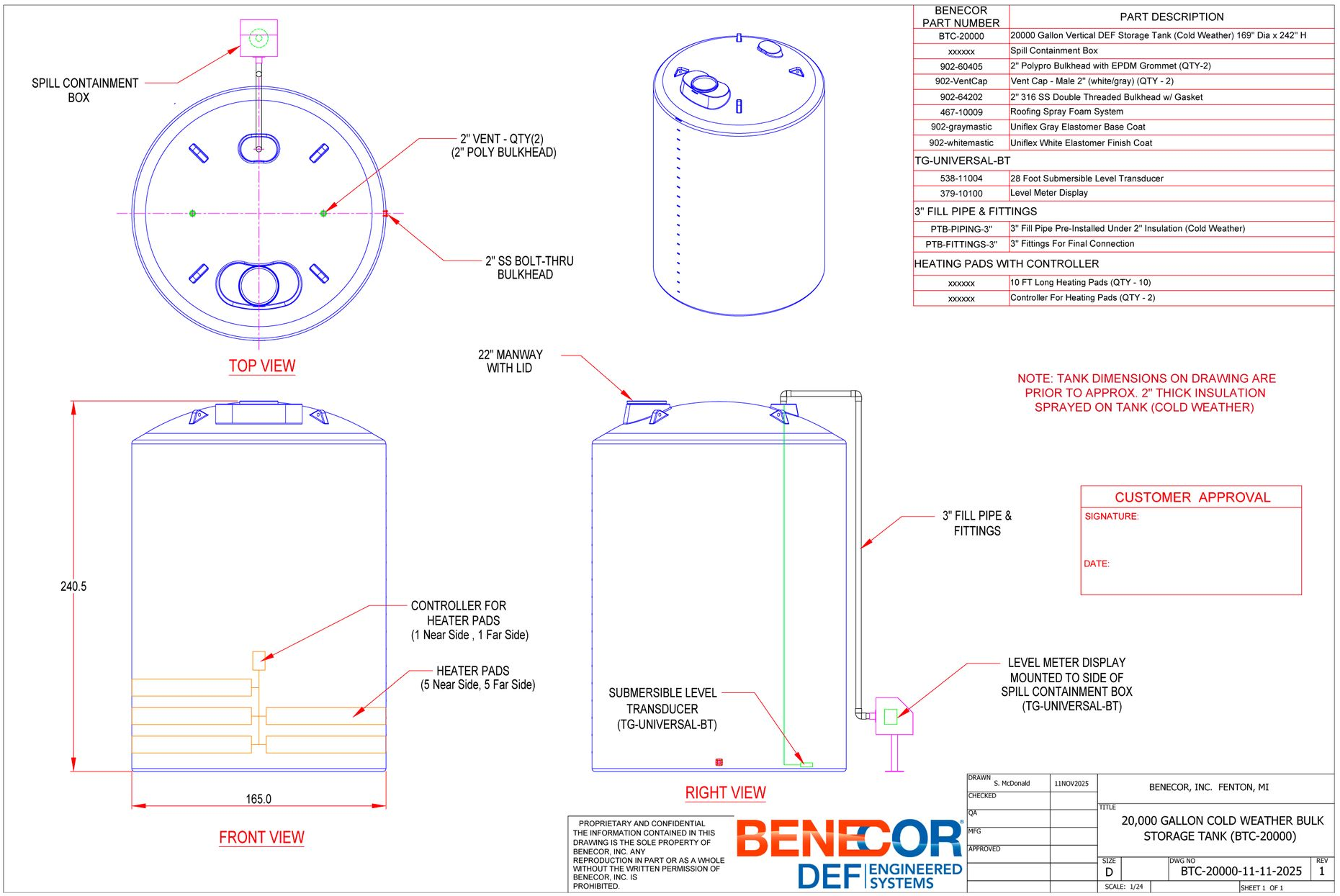

The system features a 20,000-gallon high-density polyethylene storage tank selected for chemical compatibility and long-term durability. To ensure consistent chemical temperature year-round, the tank is equipped with industrial-grade heating pads, high-performance insulation, and precision temperature controls. This proven design approach is routinely used by Benecor for highly temperature-sensitive chemicals where crystallization, separation, or viscosity changes must be avoided.

Benecor’s integrated heating and control systems deliver reliable thermal regulation, reduced energy loss, and continuous operational stability. This design directly mitigates cold-weather risks such as freezing, chemical degradation, pumping challenges, and tank stress, protecting both the stored chemical and the facility itself.

By combining chemical compatibility analysis, engineered heating and insulation, intelligent temperature control, and application-specific expertise, Benecor delivers storage systems that safeguard product quality, support uninterrupted production, and provide long-term reliability. The result is a solution that ensures GPAM is stored safely, consistently, and efficiently, regardless of seasonal temperature fluctuations, helping the paper mill meet its operational and quality objectives with confidence.