Article

Iowa’s First Retail B99 Biodiesel Site Opens with Benecor’s Cold-Climate Fuel Infrastructure Solution

Project Overview: High-Blend Biodiesel in a Cold-Weather Retail Environment

In Spring 2025, Iowa’s first retail B99 biodiesel pump officially opened at the Pilot Travel Centers location in Urbandale, Iowa, between Douglas Avenue and Interstate 35 near Des Moines.

The site is one of the first in the United States to offer

B99 biodiesel (99% renewable biodiesel) at a retail pump — expanding access to high-blend biofuels for commercial fleets operating across central Iowa.

But launching a B99 retail fueling site in the Midwest required more than just adding a pump.

It required solving a cold-weather infrastructure challenge.

Why B99 Is Difficult in Cold Weather

- Biodiesel has a higher cloud point than petroleum diesel

- It can begin to crystallize or gel at temperatures well above freezing

- Thickened fuel can clog filters, restrict flow, and damage dispensing equipment

- Above-ground tanks are exposed to ambient winter temperatures

Historically, many high-blend biodiesel systems relied on underground storage tanks (USTs) to leverage the earth’s stable temperature. But for retrofit travel center projects, underground installation can be:

- Cost-prohibitive

- Operationally disruptive

- Logistically impractical

The Urbandale site needed a solution that could support year-round B99 retail sales — without requiring new underground infrastructure.

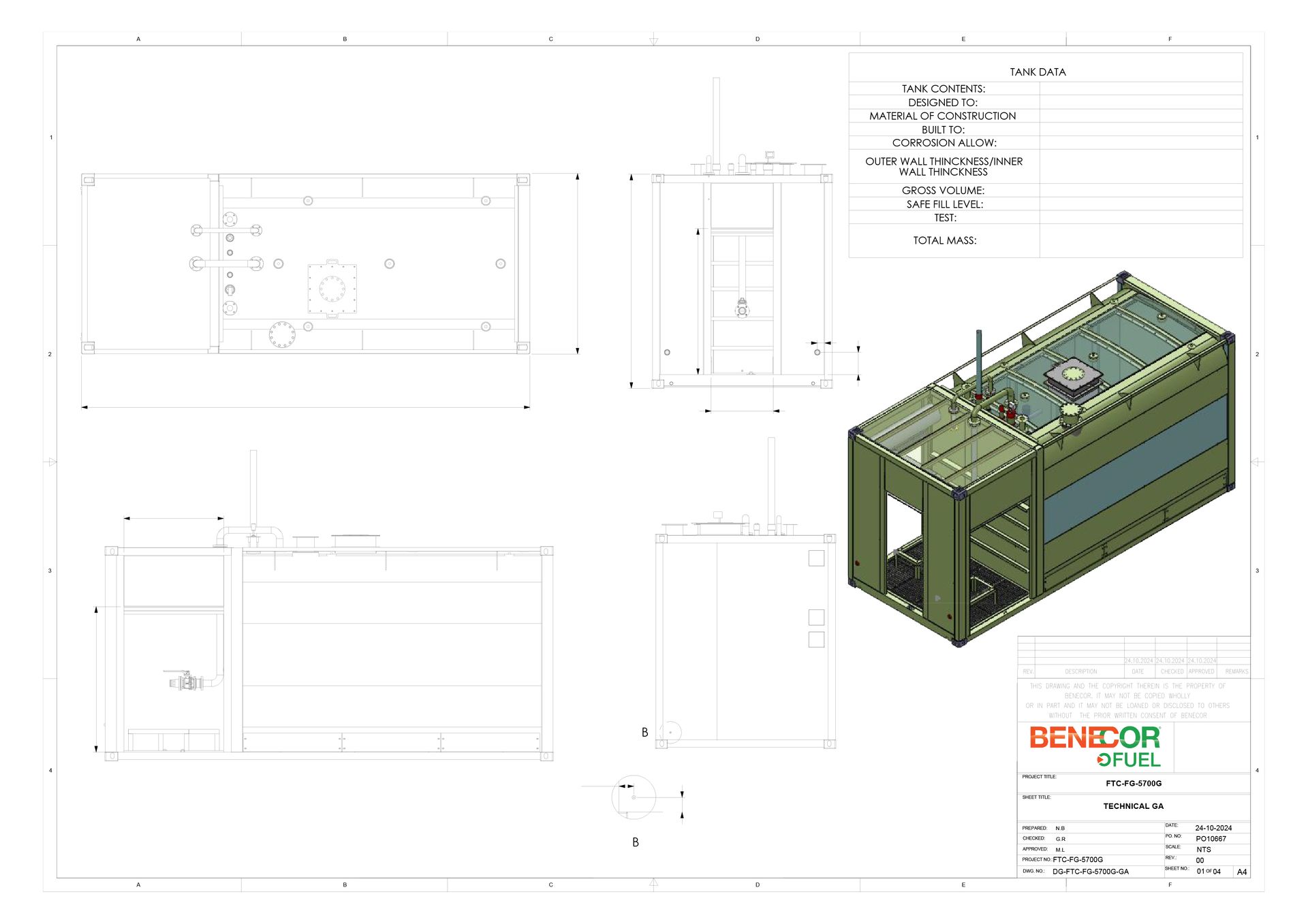

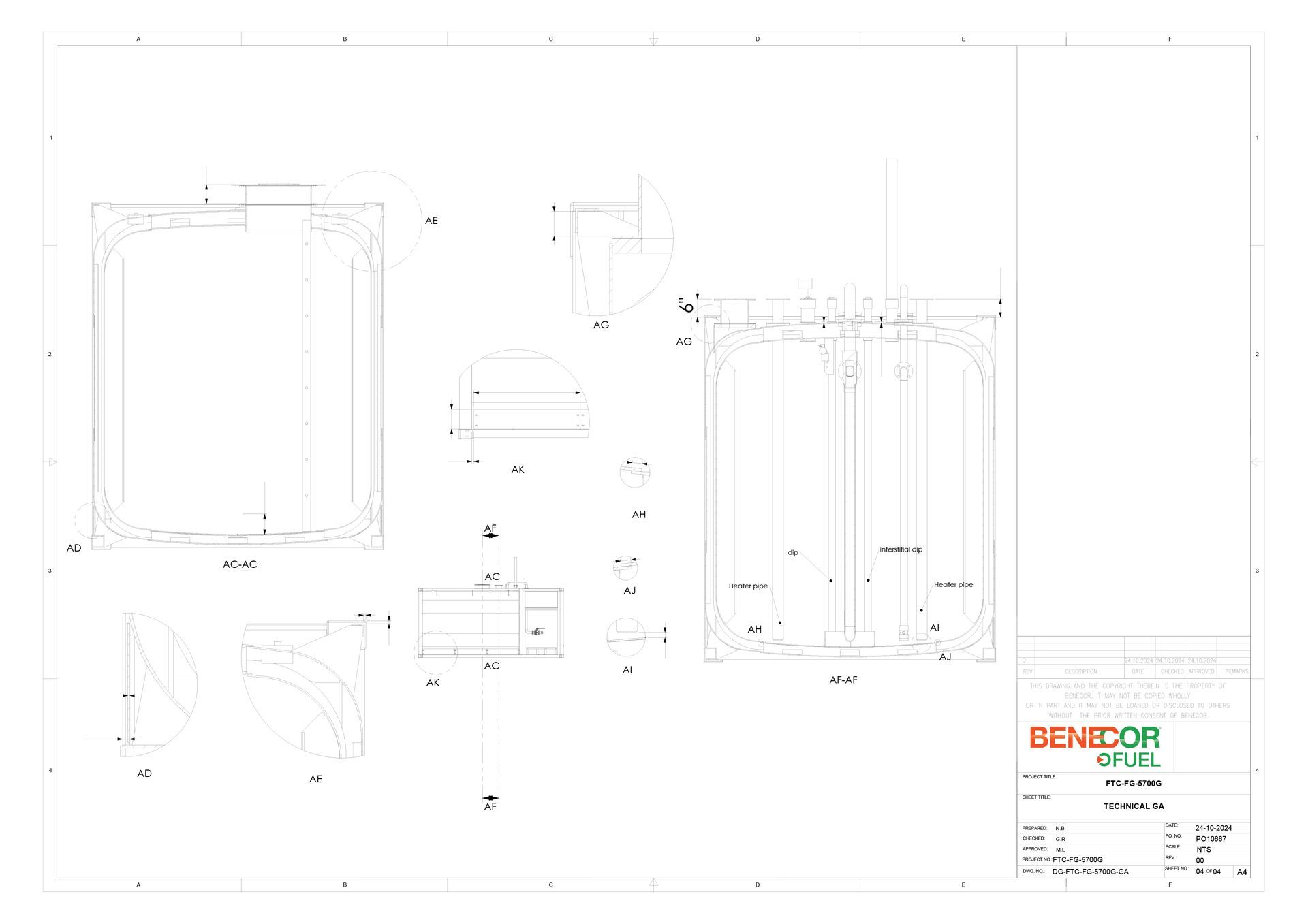

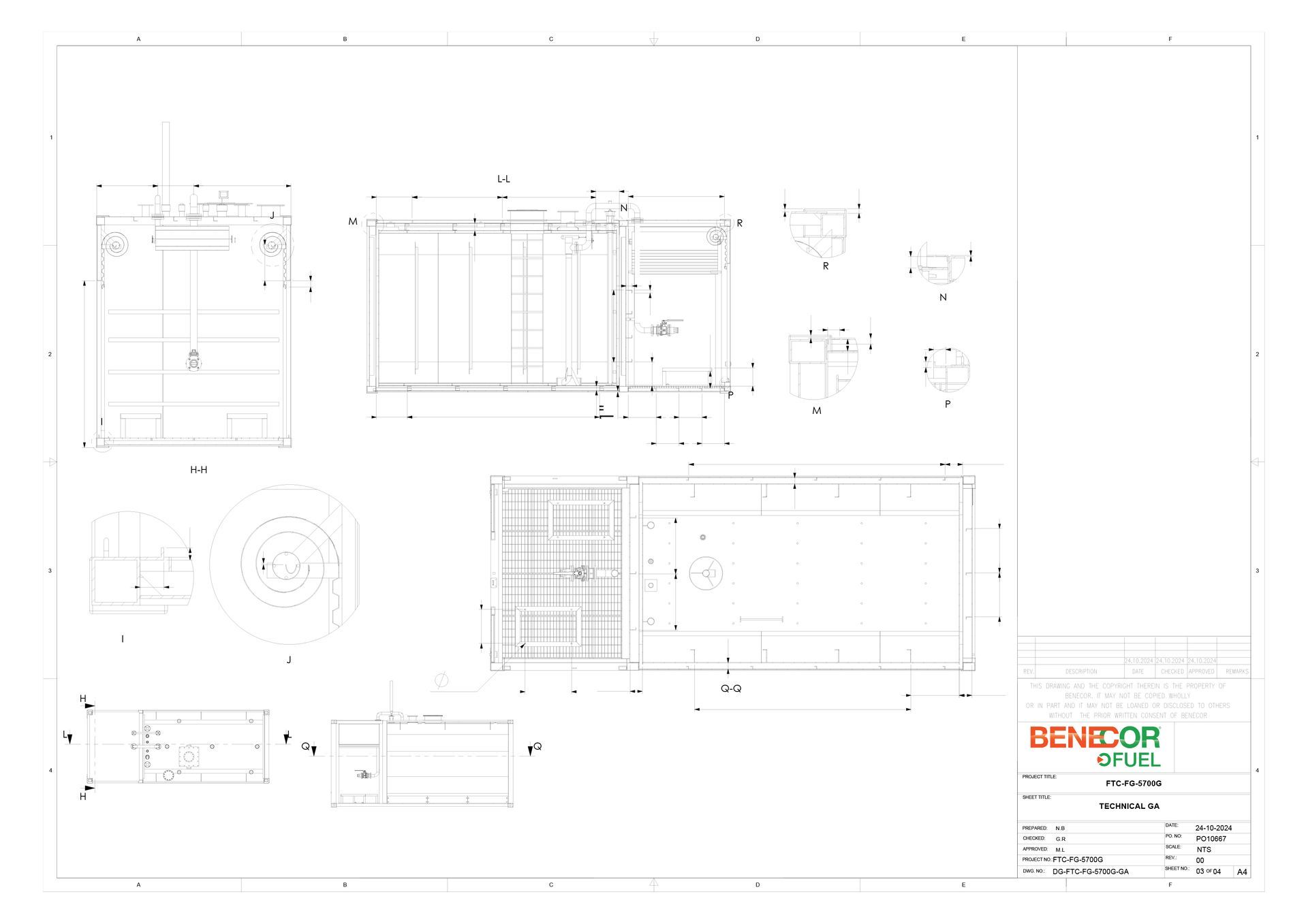

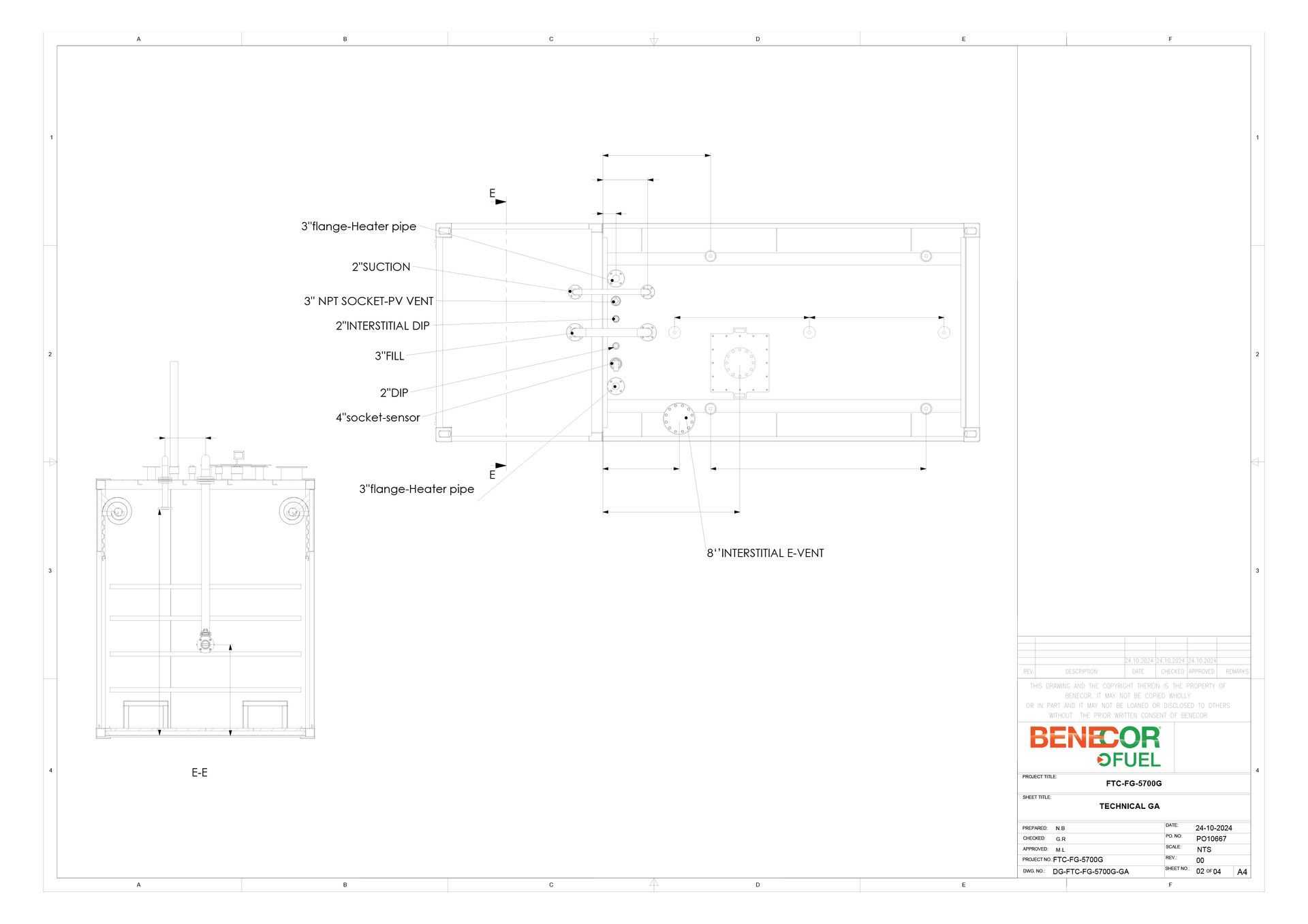

Benecor’s Solution: Engineered Above-Ground Biodiesel Infrastructure

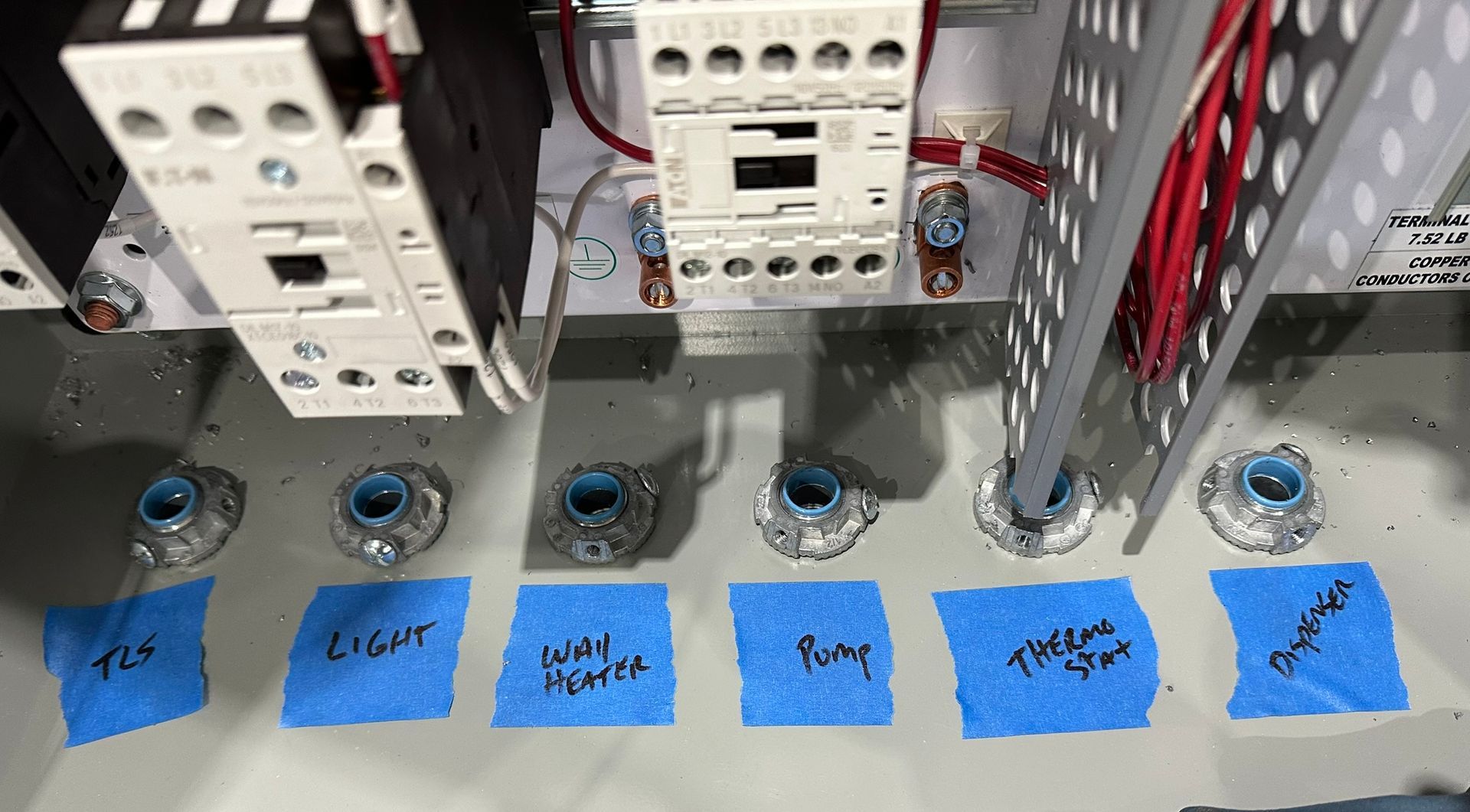

Benecor designed and manufactured a fully integrated, temperature-controlled, above-ground biodiesel storage and dispensing system engineered specifically for cold-climate operation. Instead of relying on underground tanks, Benecor developed a

turnkey above-ground system that maintains fuel integrity in freezing conditions.

The System Included:

- Fully insulated above-ground storage tanks engineered to minimize heat loss

- Integrated heating systems and temperature controls to maintain biodiesel above critical cloud and gel points

- Heated piping, pumps, and dispensing components to ensure uninterrupted fuel flow

- On-site blending capability, allowing biodiesel and diesel to be blended as needed

This approach eliminates the need to store large volumes of pre-blended fuel and provides flexibility to adjust blend levels based on operational and market conditions.

The entire system was engineered and manufactured in Michigan, then delivered and installed as a turnkey solution tailored to the specific operational demands of high-blend biodiesel in a Midwestern retail fuel environment.

Why On-Site Blending Matters for Fuel Retailers

According to Benecor Owner Brendan Foster:

“We’re talking to other folks out there who are also asking how they can get the higher biofuel rates. On-site blending means we’re able to provide a fairly inexpensive approach for the Pilots of the world to take advantage of available credits and offer now another outlet for biodiesel.”

By integrating blending capability within a heated, insulated above-ground system, Benecor enables:

- Access to renewable fuel credits and incentives

- Flexible fuel blending without additional underground tanks

- Protection of fuel quality in cold climates

- Scalable infrastructure for future biofuel expansion

For travel centers and fleet fueling operations, this means

lower installation complexity, controlled capital costs, and reliable year-round biodiesel availability.

The Result: A Scalable Model for Cold-Climate Renewable Fuel Deployment

The Urbandale project demonstrates how engineered system design can overcome the cold-weather limitations traditionally associated with high-blend biodiesel.

With Benecor’s purpose-built storage, blending, and dispensing infrastructure, the Pilot Travel Centers site now serves as a real-world model for:

- Retail B99 biodiesel deployment

- Cold-climate above-ground fuel storage

- Scalable renewable fuel infrastructure

- Commercial fleet biofuel adoption

State and agricultural leaders recognized the opening as a milestone in strengthening Iowa’s renewable fuel supply chain — connecting soybean production to lower-carbon transportation solutions at the retail pump.